Group profile

ABOUT US

About us

Development, textile, printing and dyeing, sales coordinated development, both domestic and foreign trade, integrated management

Located in Shaoxing Binhai Industrial Park, Zhejiang Rainbow Village Printing and Dyeing Co.,Ltd. covers an area of 350 mu with a total investment of nearly 250 million yuan.

The company has a large number of senior technical personnel, and foreign experts * engaged in process technology development and production site management. The main equipment includes high-precision wide-width flat screen in Boussey, rotary screen printing machine ALLFIT, Eco-8, EC038 Ericsson dyeing machine, “Monfons328” TWIN AIR8F setting machine, Italian Lafa KSA pre-shrinking machine, Ultrasoft GSI-106 sanding machine, Korean steam machine, Italian mercerizing singeing machine, automatic dripping system, automatic mixing system, computer color separation system, computer sketch system.

Mainly engaged in cotton, mercerized cotton, hemp, chemical fiber (including texturing, jacquard, etc.) needle, woven fabric printing and dyeing production, and all the use of environmentally friendly dyes auxiliaries. Product positioning in the high-end, export-oriented, for fashion, sports, casual wear, t-shirts, lycra clothing, home textiles and other products.

In order to expand export, the company set up offices in Shanghai, Guangzhou, exhibition hall, specializing in foreign trade business. The company will according to the company“Development, textile, printing and dyeing, sales coordinated development, both domestic and foreign trade, integrated management” and ideas, to provide domestic and foreign customers * products and excellent services. We will create a good space and stage for you to do their best!

Zhejiang Rainbow Village Printed and Dyeing Co.,Ltd

The company was founded in 2002

Zhejiang Rainbow Village Printed and Dyeing Co.,Ltd. was founded in 2002

Covering an area of 350 acres

Investment of 2 billion yuan

Annual production of 16200 tons of knitted dyed fabric

Annual production of 50 million meters of woven dyed fabric

Printed fabric over 55 million meters

Annual production capacity of 26700 tons

Company picture

Company picture

Company picture

Company picture

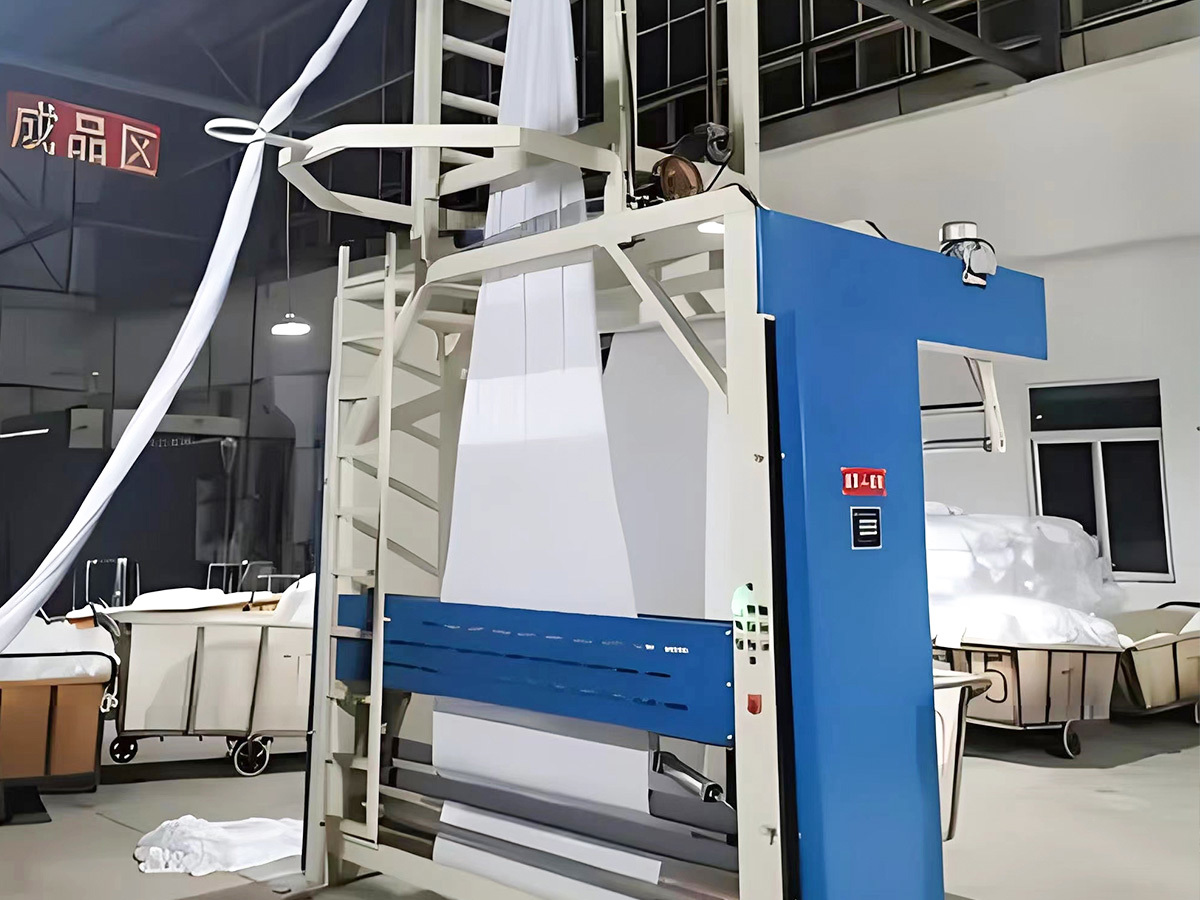

Printing and Dyeing Workshop

The main equipment is equipped with Swiss Boussey high-precision, wide-width Japanese seongping network, rotary screen printing machine, ALLFIT, Eco-8, EC038 Ericsson dyeing machine “Monfons328” TWIN Air8f Shaping Machine, Italy Rafa KSA pre-shrinking machine, ultrasoftgsi-106 sanding machine, Korean steam machine, Italy mercerizing singeing machine and a series of advanced machines. The annual production capacity reaches 162 million tons of dyed cloth and over 55 million meters of printed cloth.

Production Equipment

The company has imported 128 single-and double-sided computer circular machines from Germany, including Terrot and Elana Meyer, which are the most advanced machines in the world. With an annual production capacity of 537600 tons

Sustainable production of green ecology and environmental protection

Green waters and blue mountains, symbolizing mountains of gold and silver, hold profound significance for Rainbow Zhuang Group in its ongoing process of upgrading and development. The group is deeply committed to environmental protection, emphasizing the harmonious coexistence of humanity and nature. It steadfastly adheres to the fundamental national policies of resource conservation, environmental protection, and sustainable development.

Rainbow Zhuang Group has taken the lead in the dyeing and printing industry by implementing technological transformations such as 'coal-to-gas,' yielding significant energy savings and emission reductions. The company exclusively employs internationally advanced low liquor ratio dyeing vats, with a soft water treatment system achieving a 16% PPM efficiency. All dyeing and finishing equipment incorporates a cooling water recycling system, and the produced wastewater undergoes comprehensive treatment. After meeting factory standards, the wastewater undergoes further processing in a specialized wastewater treatment facility. The two-stage treatment process ensures full compliance with emission standards.